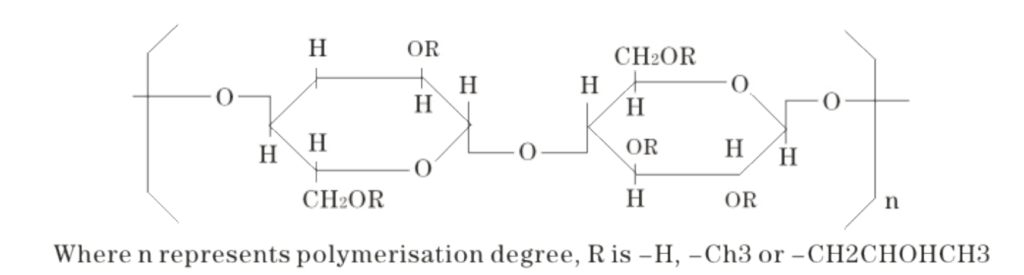

HYDROXYPROPYL METHYL CELLULOSE(HPMC)

HPMC is the main additive of ready-mixed mortar. Although the addition of cellulose ether is very low, it can significantly adjust the performance of mortar. It can adjust the consistency, workability, adhesion and water retention of mortar. It plays a very important role in the field of ready-mixed mortar.

1.Low viscosity hydroxypropyl methyl cellulose has an important effect on the water retention consistency and workability of self-leveling mortar. On the premise of normal mortar composition, the fluidity of mortar can be adjusted by changing the content of cellulose ether.

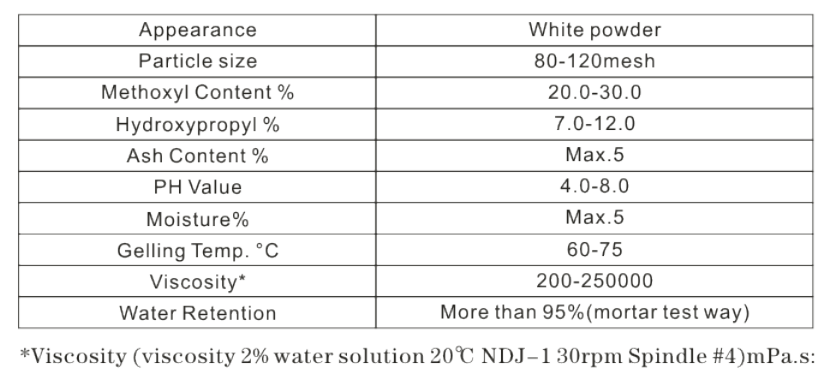

2.In order to fully hydrate the gel material, an appropriate amount of HPMC can maintain the moisture in the mortar for a long time. The viscosity of HPMC also has a great influence on the water retention of mortar. The higher the viscosity, the better the water retention. Hydroxypropyl methyl cellulose with a general viscosity of 400 mpa. It is mainly used for self-leveling mortar, which can improve the leveling performance and compactness of mortar.

3.The setting time of mortar increases with the increase of cellulose ether content. The retarding effect of HPMC on cement paste mainly depends on the degree of alkyl substitution, and has little relationship with its molecular weight. The higher the content of cellulose ether, the more obvious the retarding effect of composite membrane on early hydration of cement.

The cellulose added in the putty powder is mainly due to the water retention property of hpmc, so that the slurry will not crack due to drying too fast after application, and the strength after hardening will be enhanced.

When putty powder is used for operation, hydroxypropyl methyl cellulose is usually added. The role of hydroxypropyl methyl cellulose in construction is water retention, construction and thickening.

1. Water retention: make the putty powder dry slowly and assist the lime calcium to react under the action of water.

2. Construction: cellulose has lubricating effect and can make putty powder have good workability.

3. Thickening: cellulose can thicken and play a role in suspension, keeping the solution uniform up and down, and resisting sagging.

HPMC has the following characteristics in joint filler

1.Hydroxypropyl methyl cellulose can provide proper viscosity for the joint filler, making it have good plasticity and easy processing;

2.The water retention property of hydroxypropyl methyl cellulose makes the mud fully hydrated, which can prolong the working time and avoid cracking;

3.Anti-slip property of hydroxypropyl methyl cellulose: it can be used as a strong adhesive on the surface of the paste without sagging

Application of hydroxypropyl methyl cellulose (HPMC) in ceramics:

1.In the ceramic industry, it is used as an adhesive for molding surprise ceramic products, giving lubricity and water retention, and improving the original strength of raw materials.

2.The concentrated solution is adsorbed on the surface of ceramic particles to reduce the friction between particles and enhance their lubricity, so that the molded products have the required surface finish and dimensional stability;

Contact Us

At Jinghong Chemical, we value building long-term partnerships with our clients. If you are looking for top-quality cellulose products or have any inquiries about our offerings, please don’t hesitate to reach out. Our dedicated team is ready to assist with tailored solutions to meet your specific business needs.